How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

Table of Contents

Introduction

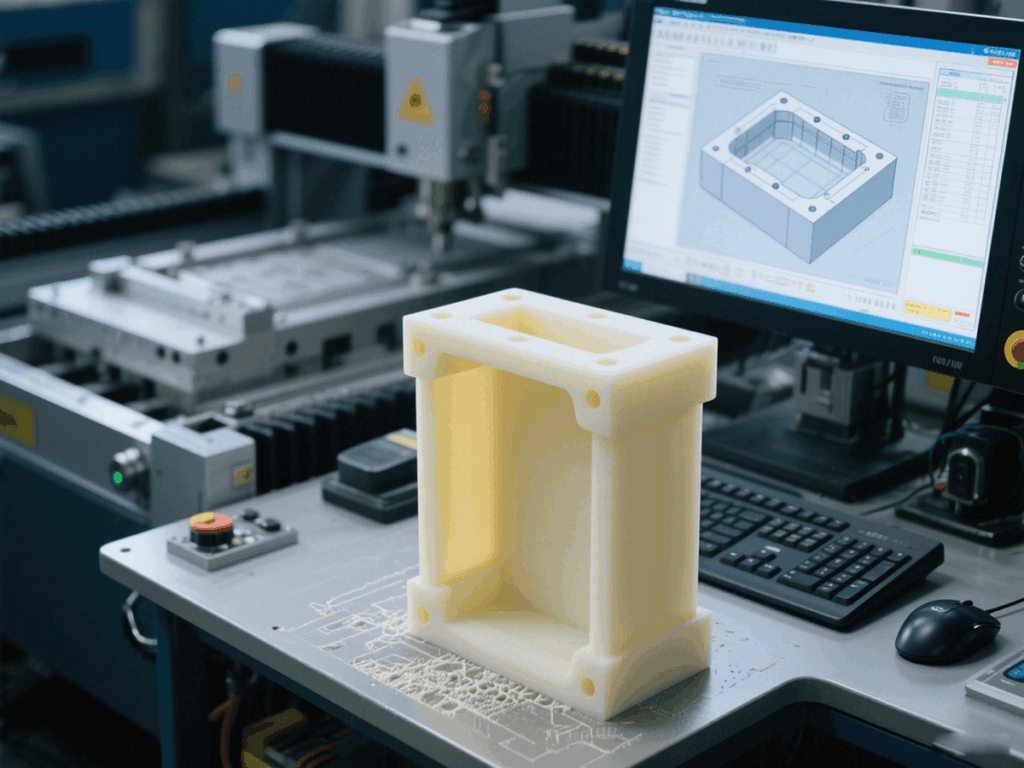

For custom braces such as AFOs (Ankle Foot Orthoses), TLSOs (Thoraco-Lumbo-Sacral Orthoses), or other supports, polyurethane foam is a favored material due to its lightweight, machinable, and cost-effective properties. This guide walks you through the process of creating orthopedic molds using 4 axis polyurethane carving CNC.

CNC Mill Polyurethane Orthopedic Molds

For custom braces such as AFOs (Ankle Foot Orthoses), TLSOs (Thoraco-Lumbo-Sacral Orthoses), or other supports, polyurethane foam is a favored material due to its lightweight, machinable, and cost-effective properties. This guide walks you through the process of creating orthopedic molds using CNC technology.

Choosing the Right Materials and Equipment

To begin the CNC mold-making process, selecting proper materials and equipment is crucial. The most commonly used material is high-density polyurethane foam, also known as tooling board. It comes in varying densities (typically between 10 to 30 lb/ft³) and offers excellent machinability.

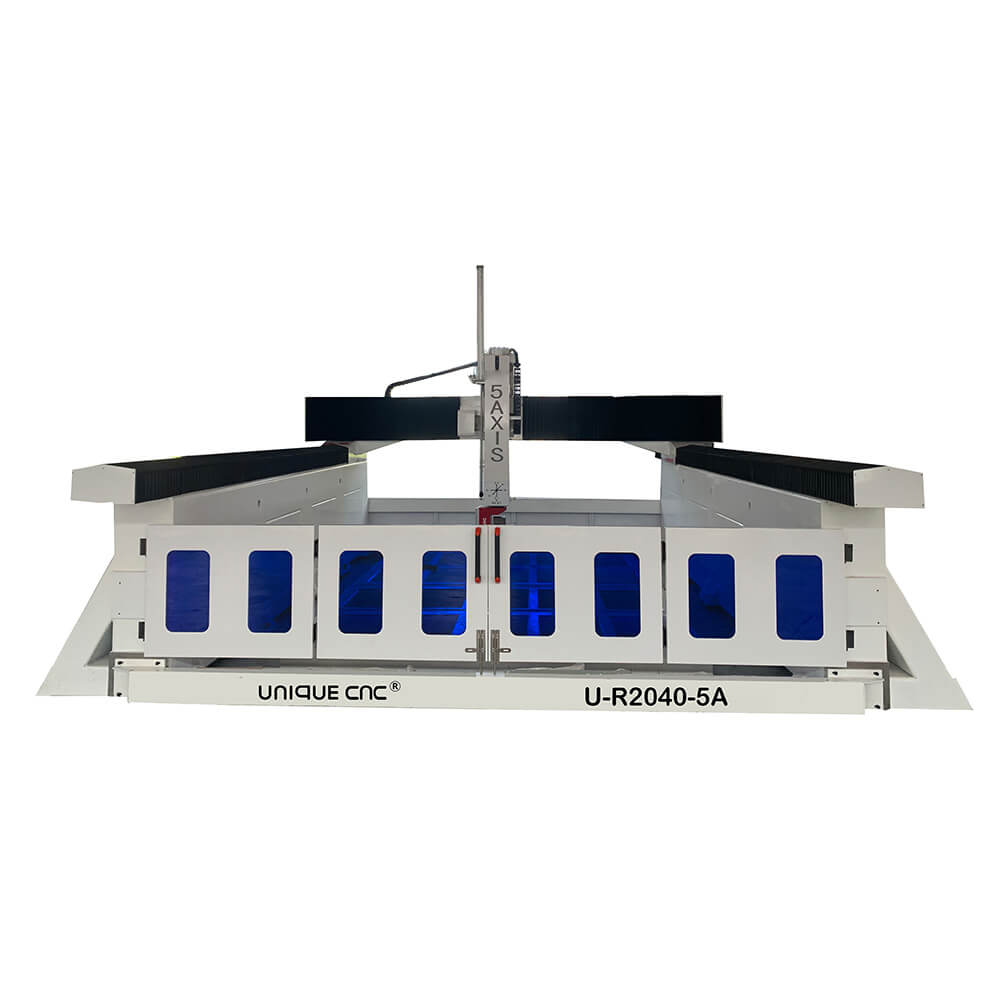

Your Polyurethane CNC Carving Machine should be:

At least a 3-axis router or milling machine

Equipped with proper fixturing or a vacuum bed

Paired with dust extraction to safely manage fine polyurethane dust

Essential tools include:

Flat end mills for roughing

Ball nose cutters for finishing

Protective gear (mask, goggles, gloves)

Capturing and Preparing 3D Patient Data

Accurate 3D modeling begins with a high-quality 3D scan of the patient’s limb or body section. Use structured light or laser scanners to capture precise surface geometry. Once you have the scan:

Import it into a CAD program (like Mastercam,Fusion360,Powermill,etc)

Clean up the mesh and remove artifacts

Add modifications such as reliefs or functional adjustments

Export the file in STL or OBJ format for CAM programming

Digital modeling ensures that every brace is precisely tailored to the patient’s anatomy.

Generating the CAM Toolpaths

In the CAM stage, the 3D model is translated into toolpaths that guide the CNC machine. Toolpath strategy typically involves:

Roughing Pass: Quickly removes bulk material using a large flat end mill.

Finishing Pass: Uses a ball nose tool to smooth fine contours and details.

Parameters such as spindle speed, stepover, and feed rates should be carefully adjusted depending on foam density and cutter diameter. Always run a simulation to verify toolpath quality and collision risks before machining.

Executing the CNC Milling Carving Process

With the material secured on the machine bed and the G-code loaded, it’s time to start cutting. Set the origin (zero) for all axes, and begin with the roughing stage followed by finishing. Monitor the milling operation to ensure there are no issues with tool wear, dust buildup, or machine alignment.

After milling:

Vacuum all foam chips and dust

Sand or smooth the mold surface manually if needed

Apply a surface sealant if the mold will be used for vacuum forming

Using the Mold to Create a Custom Orthotic Brace

Once your polyurethane mold is ready, it can be used for thermoforming or lamination to produce the final custom brace. Common steps include:

Heating thermoplastic sheets

Vacuum forming the sheet over the mold

Trimming and finishing the brace

Fitting and adjusting it for the patient

The mold can also be archived for future reproductions, reducing turnaround time for repeat orders.

Conclusion

Polyurethane CNC Carving Machine brings a new level of efficiency and precision to orthotic fabrication. By combining 3D scanning, CAD/CAM software, and advanced machining, orthotists and technicians can produce highly customized, professional-grade braces with minimal manual effort. Whether you’re building AFOs, KAFOs, or spinal braces, investing in digital workflows will enhance your production capabilities and improve patient outcomes.

Comments

Related Products

How 5 Axis CNC Routers Revolutionize Automotive Interior Manufacturing?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials.

Tags

The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials.

How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

How is an Orthopedic Mold CNC Router Revolutionizing Scoliosis Correction and Rosthetic Mold Fabrication?

Orthopedic molds carved by a CNC carving machine can reduce the inconsistencies, ensuring braces mirror the patient’s unique spinal contours.