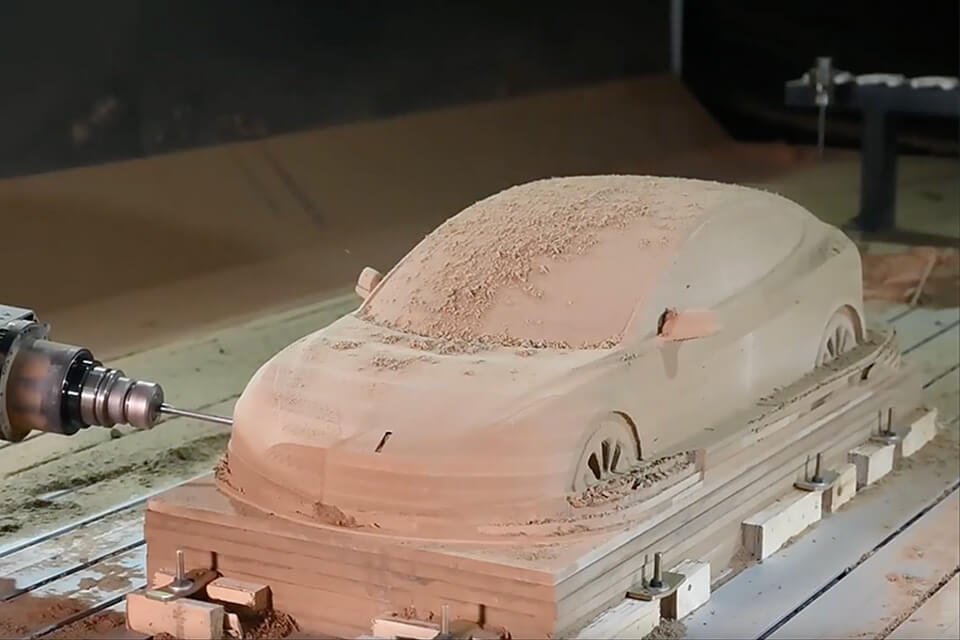

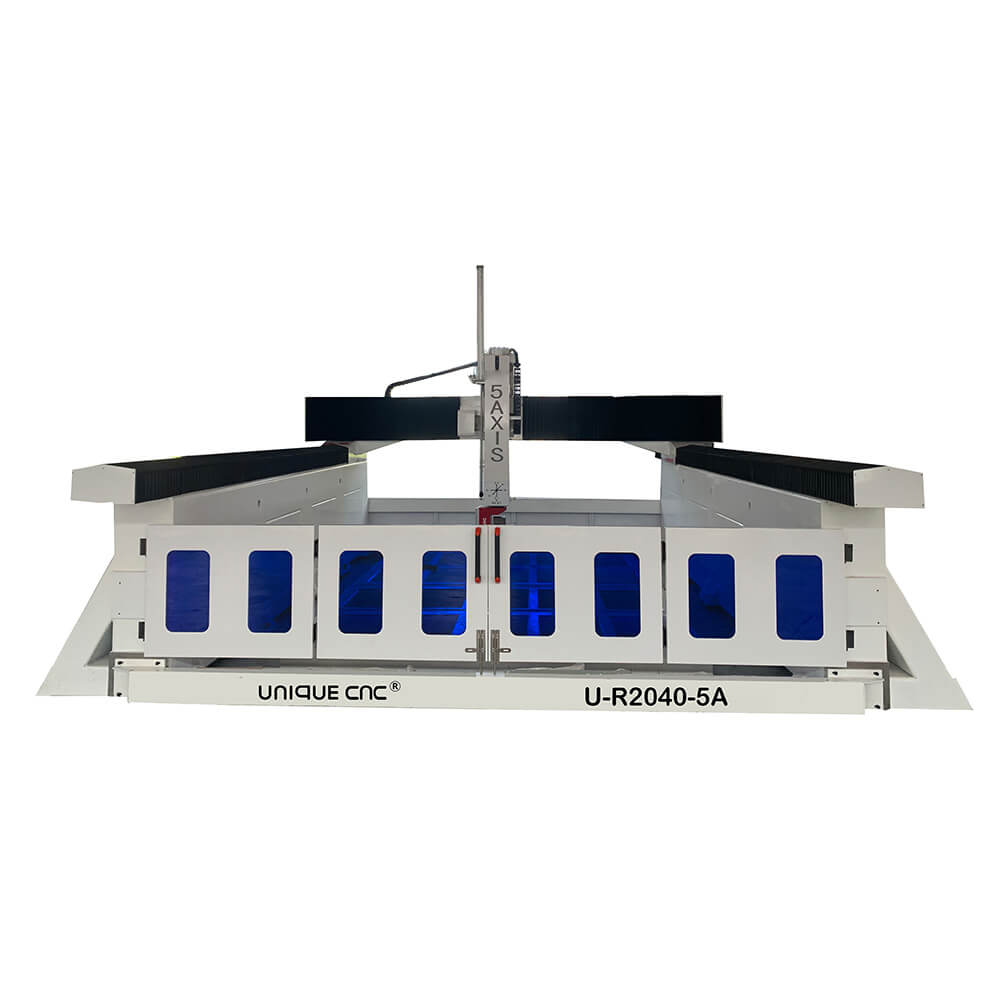

The 5 axis CNC carving machines totally changed the automotive interior industry. They let designers mix cool, creative looks with super-precise functionality, so they can produce complex, custom-made parts that are seriously high-quality.

Here’s the best part: the 5 axis CNC machines almost can handle all kinds of materials, and the 5-axis movement means they handle detailed and complicated designs. That makes them perfect for prototyping new ideas, making limited-edition luxury parts, and quickly testing designs, especially now that the industry’s moving toward eco-friendly materials and sleek, tech-forward interiors.