The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Table of Contents

Introduction

In the vast field of modern manufacturing, the innovative application of materials and equipment is constantly shaping the development pattern of the industry. Epoxy resin molds, with their unique advantages, have emerged in many fields; while 5-axis engraving machines, as advanced CNC machining equipment, are revolutionizing manufacturing processes with their high-precision and high-flexibility machining capabilities. When these two are organically combined, a new door to efficient, precise, and diversified production is opened.

What is Epoxy Resin Mold?

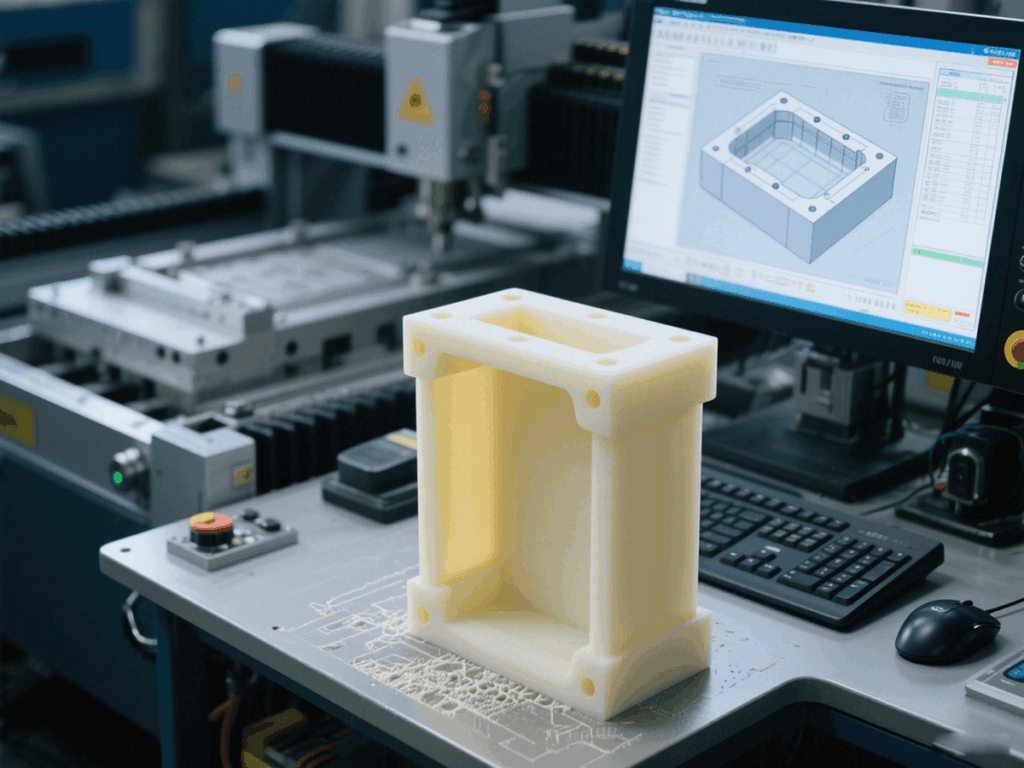

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials (such as glass fiber cloth, carbon fiber cloth, etc.). It has many significant characteristics, bringing new vitality to mold manufacturing.

Advantages of Epoxy Resin Molds?

High-Precision Replication and Detail Expression

Short Production Cycle and Cost-Effectiveness

Compared with the complex processing procedures of traditional metal molds (such as forging, mechanical cutting, grinding, etc.), the production process of epoxy resin molds is relatively simple. The molding process of the mold can be quickly completed through pouring, curing and other processes. For some molds with complex shapes that are difficult to manufacture through traditional mechanical processing, epoxy resin molds can be formed in one time by pouring or low-pressure molding, without relying on large precision cutting machine tools, which greatly shortens the production cycle. At the same time, its material cost is relatively low, and the cost advantage is particularly prominent in small-batch production or prototype trial production in the product research and development stage. For example, in the small-batch customized production of auto parts, the use of epoxy resin molds can significantly reduce the initial mold investment cost and speed up the product launch.

Good Chemical Stability and Durability

The cured epoxy resin mold has excellent resistance to various chemical reagents and is not easily eroded by acids, alkalis, solvents, etc. This enables it to maintain stable chemical properties when in contact with various molding materials, ensuring the long-term use of the mold. Moreover, epoxy resin molds have certain strength and hardness. Although they are not as good as metal molds under some extreme conditions, they are sufficient to withstand multiple demolding operations and normal production wear in general production environments, and have a long service life, reducing the time and cost waste caused by frequent mold replacement.

Based on these characteristics, epoxy resin molds are widely used in many industries. In the field of handicraft manufacturing, they are used to make molding molds for plaster statues, resin ornaments, hand-made models, etc., helping creators transform design inspiration into exquisite physical objects; in the architectural decoration industry, they can make molds for special-shaped decorative components (such as gypsum lines, relief panels, etc.) to meet personalized design needs and add unique charm to buildings; in the electronics industry, they are often used to manufacture molds for electronic component casings and circuit board packaging, protecting internal precision components and ensuring stable product performance.

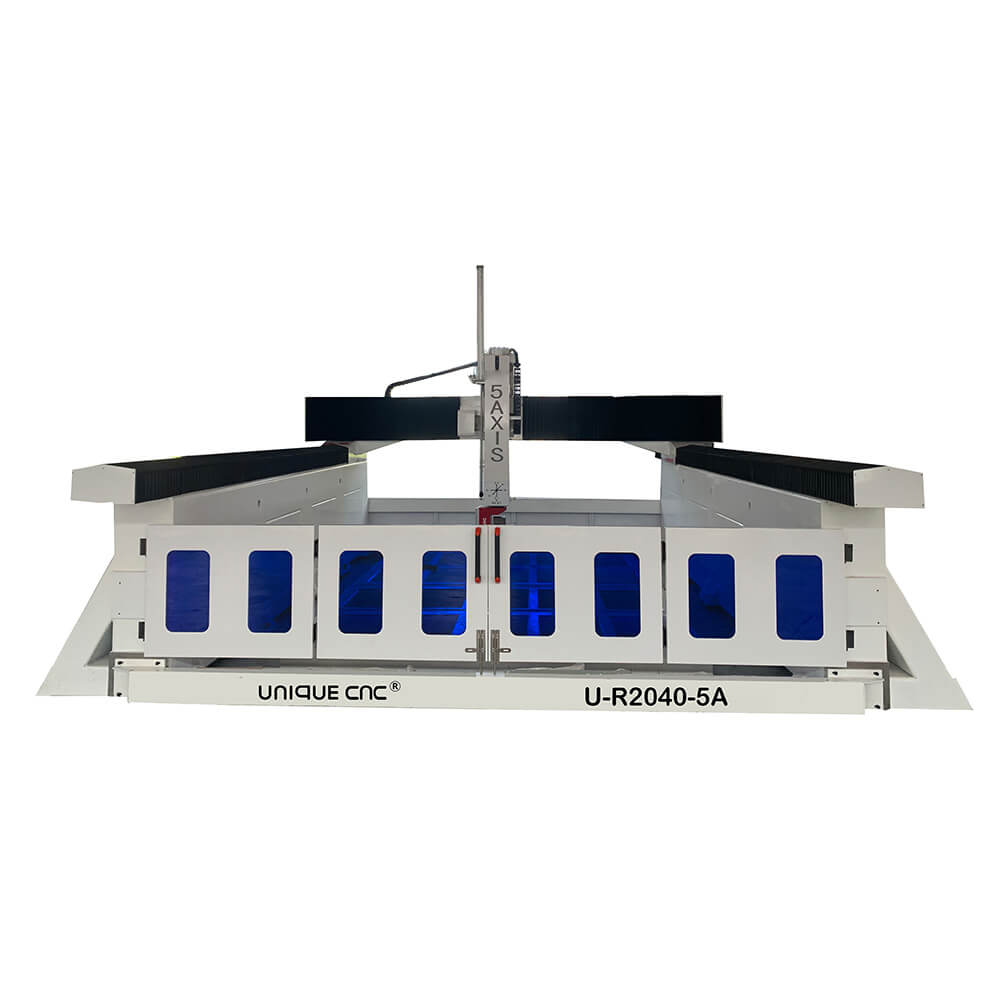

High-Precision Machining of Complex Molds

In the mold manufacturing process, traditional processing methods are often difficult to meet the precision requirements for some molds with complex internal structures and appearance shapes. However, using 5-axis engraving machines to process epoxy resin molds can give full play to their multi-axis linkage advantages. 5-axis engraving machines can accurately perform milling, drilling, engraving and other operations on epoxy resin molds, and easily realize the processing of special-shaped cavities inside the mold, fine runner structures, and complex patterns on the mold surface. For example, in the manufacturing of automobile engine block molds, the cooling water channel structure inside the mold is complex. Using 5-axis engraving machines to process epoxy resin molds can accurately complete the engraving of the water channel according to the design requirements, ensuring the dimensional accuracy and surface quality of the cooling water channel, thereby improving the casting quality and performance of the engine block. This high-precision processing capability not only improves the quality of the mold but also provides a reliable guarantee for the subsequent production of products.

Personalized Custom Production

With the increasing diversification of market demand, personalized custom production has become the development trend of the manufacturing industry. The characteristics of low cost and short production cycle of epoxy resin molds make them very suitable for mold making of personalized custom products. Combined with the flexibility of 5-axis engraving machines, enterprises can quickly design and produce unique epoxy resin molds according to customers’ personalized needs. Through 5-axis engraving machines, various personalized patterns, logos or unique designs structures can be engraved on the mold surface, and then the mold can be used for product production, which can meet customers’ personalized requirements for product appearance and function. In the furniture customization industry, customers may have unique design ideas for furniture handles, decorative components, etc. Enterprises can quickly respond to customer needs by using the combination of epoxy resin molds and 5-axis engraving machines, produce unique furniture components, and improve customer satisfaction and the enterprise’s market competitiveness.

Rapid Prototype Production and Product Iteration

In the product research and development stage, rapid prototype production and iterative optimization are crucial to shorten the product launch cycle. The combination of epoxy resin molds and 5-axis engraving machines provides an efficient solution for this. 5-axis engraving machines can be used to quickly process the design model into epoxy resin molds, and then the product prototypes can be produced through the molds. Due to the low cost of making epoxy resin molds, enterprises can produce multiple different versions of molds in a short time to repeatedly test and improve product prototypes. For example, in electronic product research and development, prototypes of mobile phone cases, tablet computer brackets and other products can be quickly produced in this way to optimize their appearance design and human-computer interaction experience, and timely find and solve potential problems before the product is officially put into mass production, improving the success rate and market adaptability of the product.

Improve Production Efficiency and Reduce Costs

From the perspective of production efficiency, the combination of the efficient processing capacity of 5-axis engraving machines and the rapid production characteristics of epoxy resin molds has greatly shortened the entire production cycle. In the traditional production mode, making complex molds requires a lot of time and high cost. Now, using 5-axis engraving machines to process epoxy resin molds can quickly complete mold manufacturing and put them into production, improving production efficiency. At the same time, due to the relatively low cost of epoxy resin molds, the initial investment in mold making is reduced. Moreover, the high-precision processing of 5-axis engraving machines reduces the rejection rate and the cost loss caused by product quality problems. In the toy manufacturing industry, if traditional metal molds are used to make molds for a new toy, the cost is high and the production cycle is long. However, using epoxy resin molds with 5-axis engraving machines can not only quickly produce molds but also ensure product quality during production, reduce production costs, and make enterprises more competitive in the fierce market competition.

Conclusion

Comments

Related Products

How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials.

Tags

The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials.

How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

How is an Orthopedic Mold CNC Router Revolutionizing Scoliosis Correction and Rosthetic Mold Fabrication?

Orthopedic molds carved by a CNC carving machine can reduce the inconsistencies, ensuring braces mirror the patient’s unique spinal contours.