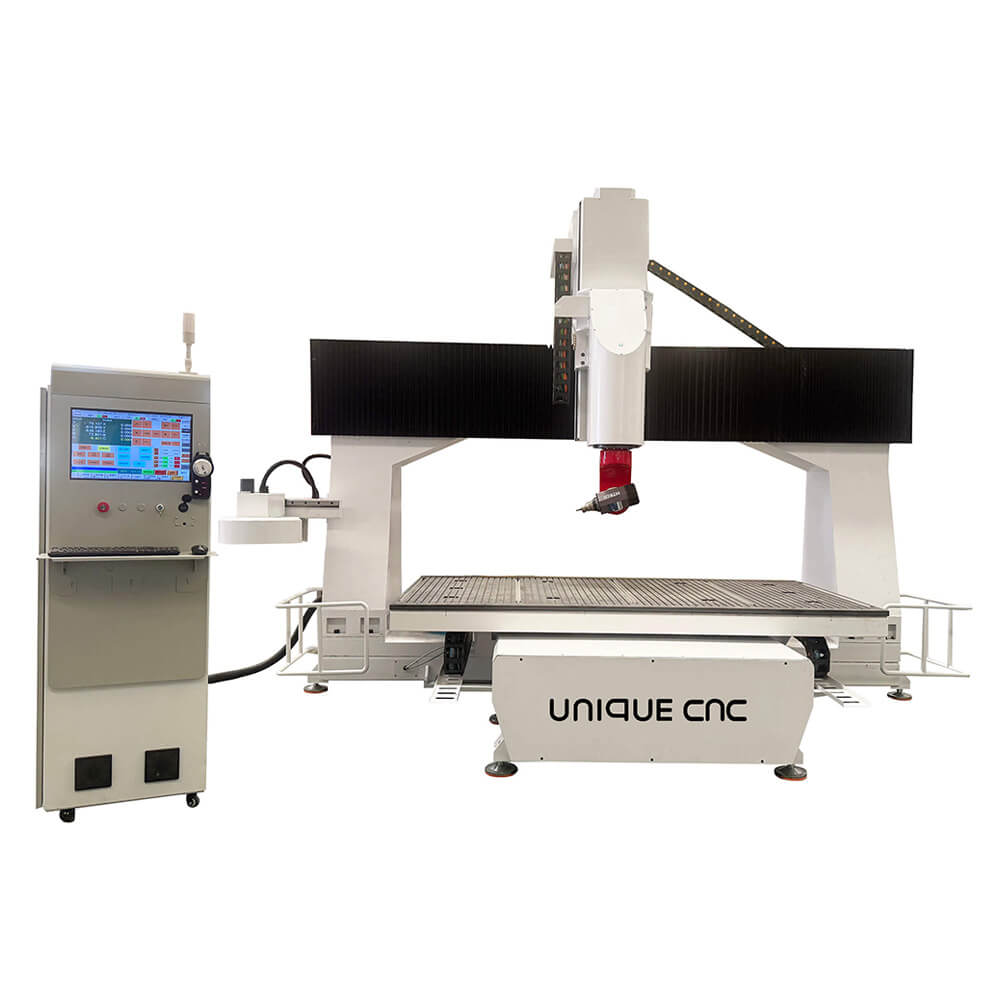

Precision 5 Axis CNC Router For Carbon Fibre Cutting Trimming Drilling

- Brand: UNIQUE CNC

- Model No.: U-R2040-5A

- Table Size: 2000x4000mm

- Price Range: $68,000-$88,000

- Standard: Meeting CE Standards in Terms of Quality & Safety

- Warranty: One-Year Limited Warranty for Entire Machine

- Shipping: Global Logistics and International Shipping for You

- Service: Lifetime Free Technical Support

- Support: Customized as per request

- Payment Term: TT, Credit Card,Paypal, Trade Assurance

Get A Quote

Table of Contents

Product Description

The 4×8 wood ATC CNC router machine is equipped with a linear automatic tool changer and a 12-bit tool magazine. The tool changer is attached to the gantry, which moves along with the gantry. During tool changing, the close distance between the spindle and the tools allows the tool change process to be completed in the shortest time. The 4x8ft CNC router table with ATC is ideal for wood cutting, milling, drilling, slotting, and engraving, making it widely used in the production of wood cabinets, doors, decorative items, and other furniture. In 2025, you can get such an advanced 4’x8’ ATC wood CNC router machine at a great value for only $12,000.

Check Out the Working Video of the Woodworking ATC CNC Router

What Are the Advantages of the 4x8ft Wood CNC Router with Auto Tools Changer Kit

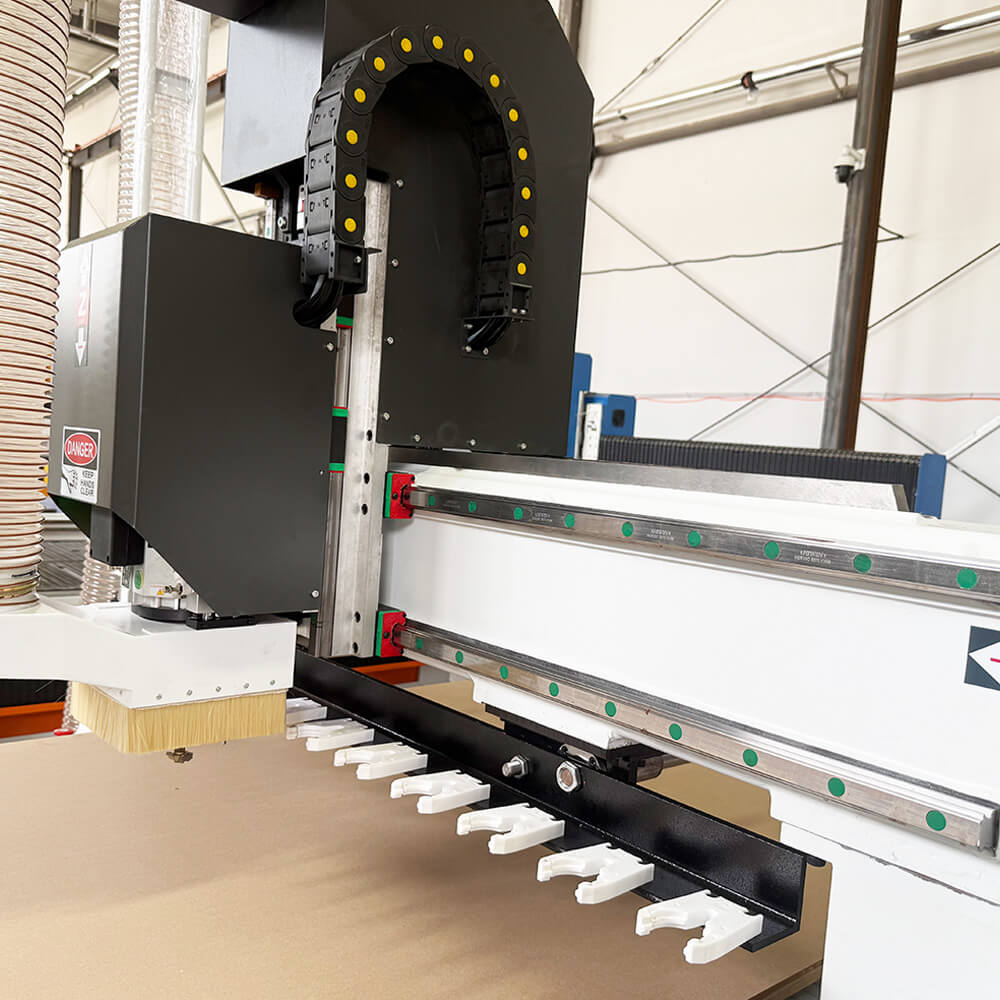

1. The linear tool magazine is attached to the gantry to maximize the speed of the automatic tool change; it can accommodate 12 router bits.

2. The spindle adopts a Chinese automatic tool change air cooling spindle with a power of 9.0KW,speed is 0-24000rpm.

3. The ATC CNC router for woodworking is equipped with AC 1500W servo motor and driver. The motors connect with Japanese Shimpo reducers make the machine fast, precise, smooth, and quiet operation. Also, the servo motors have very good acceleration and deceleration characters.

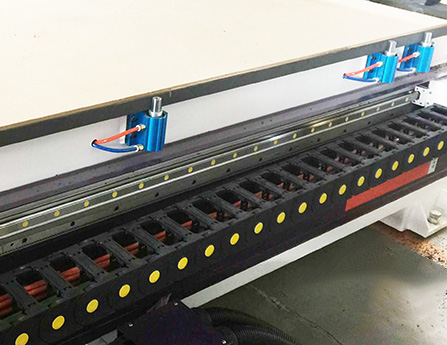

4. According to the production characteristics of panel furniture, positioning pop-up pins are designed for the 1325 wood CNC router with ATC, reducing workpiece alignment time greatly.

5. The 4x8ft Wood ATC CNC Cutting Machine is equipped with an LNC controller, offering seamless support for automatic tool change functionality within a closed-loop control system. With the closed-loop servo system, this wood ATC CNC cutting machine achieves true closed-loop operation: the servo system transmits positioning feedback to the CNC controller, which compares the real-time data against preset parameters and executes corresponding corrections.

6. The electric oil lubrication system, powered by an electric drive mechanism, enables precise, time-regulated, and metered delivery of lubricants, and ensures reliable lubrication of transmission components (such as guide rails and ballscrews). The lubricant can prevent the rails and ballscrews from wearing and rusting, thereby saving maintenance costs.

7. The panel furniture ATC CNC router is equipped with a vacuum table and vacuum pump, which serves as a critical component, primarily designed to securely hold workpieces in place during machining operations. Specifically, the vacuum table uses vacuum pressure to clamp workpieces tightly against its surface.

Auto Tool Changer CNC Router Parameters

| Model No. | U-R1325ATC Wood CNC Router |

|---|---|

| Main Feature | CNC Router with auto tool changing |

| Working Size | Standard: 1300x2500mm (4×8 feet) | Optional: 1500x3000mm (5×10 feet) |

| Working Table | PVC vacuum table with 7.5kw vacuum pump |

| Tool Storage Library | Linear 12 positions tool magazine attaches to the gantry |

| Spindle | ATC spindle, 9.0kw, 0-24000RPM, HSD or Chinese brands |

| Tool Holder | ISO30 |

| X-Axis Motion | AC Servo 1500W with Shimpo reducer |

| Y-Axis Motion | AC Servo 1500W,dual drive with Shimpo reducers |

| Z-Axis Motion | AC Servo 1500W with brake function |

| Control System | LNC, Ncstudio or Syntec |

| Electronics | Omron |

| Protection Components | Thermal protection for the motor, braking resistance, fuses |

| Linear Guides | X and Y axis: 30mm, Z axis: 25mm, high precision rails |

| X Y Transmission | Helical rack & pinion |

| Z Transmission | Rolling ballscrew and coupling |

| Working Power | AC380V/50Hz, 3Ph ( or Made to order) |

| Net Weight | 1600KGS |

| Package Dimension | 3300x2270x2100mm |

| Packing Way | Complete machine |

Daily Maintenance of the CNC Router with Tool Changer

Perform these tasks at the start or end of the day to keep the machine in good condition.

1. Clean the Work Area.Remove wood chips, dust, and debris from the table, gantry, and surrounding area using a brush, vacuum, or air compressor. Accumulated debris can interfere with movement or damage components. Wipe down the table surface with a dry cloth to prevent residue buildup, especially if working with materials like MDF (which produces fine dust).

Applicable Materials of the CNC Wood Router with Auto Tool Changer

A CNC wood router equipped with an auto tool changer is capable of processing a wide range of materials. Below are the main applicable materials:

1. Wood and Wood-Based Materials

- Solid Wood: Including hardwoods (e.g., oak, maple, walnut, mahogany) and softwoods (e.g., pine, fir, cedar). The auto tool changer allows seamless switching between tools for tasks like cutting, drilling, carving, and sanding, adapting to the varying density and hardness of different wood types.

- Engineered wood ,like plywood, MDF (Medium-Density Fiberboard), particleboard, OSB (Oriented Strand Board), and HDF.These materials are commonly used in furniture making and cabinetry, where the router’s precision ensures clean edges and detailed engravings.

- Wood Composites: Materials like veneered panels, laminate-covered wood, and resin-bonded wood strips, which require consistent tool performance for smooth processing.

2. Plastics and Polymer Materials

- Thermoplastics: PVC (Polyvinyl Chloride), acrylic (PMMA), ABS (Acrylonitrile Butadiene Styrene), polyethylene (PE), and polypropylene (PP). These materials are often used in signage, decorative panels, and custom parts, where the router can achieve precise cuts, slots, and 3D engravings.

- Foam Plastics: Expanded Polystyrene (EPS), polyurethane foam, and PVC foam boards, which are lightweight and easy to machine for packaging, prototypes, or architectural models.

3. Non-Ferrous Metals (with proper tooling)

Soft Metals: Aluminum (including aluminum alloys), brass, and copper. When paired with carbide tools (switched automatically by the tool changer), the router can perform milling, drilling, and surface engraving, making it suitable for decorative metal parts or industrial components.

4. Composite and Synthetic Materials

- Fiberglass and Carbon Fiber Composites: Used in aerospace, automotive, and marine industries for their strength-to-weight ratio. The auto tool changer enables efficient switching between cutting and trimming tools to handle these reinforced materials.

- Rubber and Gasket Materials: Including natural rubber, neoprene, and EPDM, which can be cut into gaskets, seals, or custom shapes with high precision.

Frequently Asked Question

Here are the answers to the frequently asked questions from the China ATC CNC Router manufacturer.

CAM software like Artcam, Aspire,Vcarve,Fusion360 and Mastercam are all good for this machine. These CAM software can convert 3D models into G – code, which is the command language understood by the ATC CNC Router wood machine.

Yes, it is possible.After adding the 4th rotary,the ATC wood CNC Router will be able to engrave both flat and columns. The 4th rotary can be put onto the table or next to the table.

No, there isn’t. For a 4′ x 8′ linear ATC CNC router, no disassembly is required for packaging. As a result, no assembly will be needed on your end. All you need to do is simply connect the machine to your electrical power supply, and then it will be ready to run.

Most manufacturers and suppliers of the ATC CNC engraving machines offer training to help users get familiar with the machine’s operation, software usage, and basic maintenance. After – sales support is also typically provided, which may include technical assistance over the phone or online, software updates, and access to replacement parts. It is important to clarify the details of the training and after – sales support services before purchasing the machine to ensure a smooth experience during its use.

Regular maintenance is crucial to ensure the machine’s performance and longevity. This includes cleaning the machine after each use to remove foam debris, lubricating the linear guide rails and ball screws according to the manufacturer’s recommendations (usually every few months), checking and tightening any loose components, and periodically calibrating the machine to maintain accuracy. Additionally, it is important to keep the control system clean and free from dust and moisture.

The 4x8ft wood furniture ATC CNC Router voltage can be 220V,380V,480V and so on.

Yes, customized sizes are highly acceptable. The drywall CNC Router can be manufactured according to customer`s request.