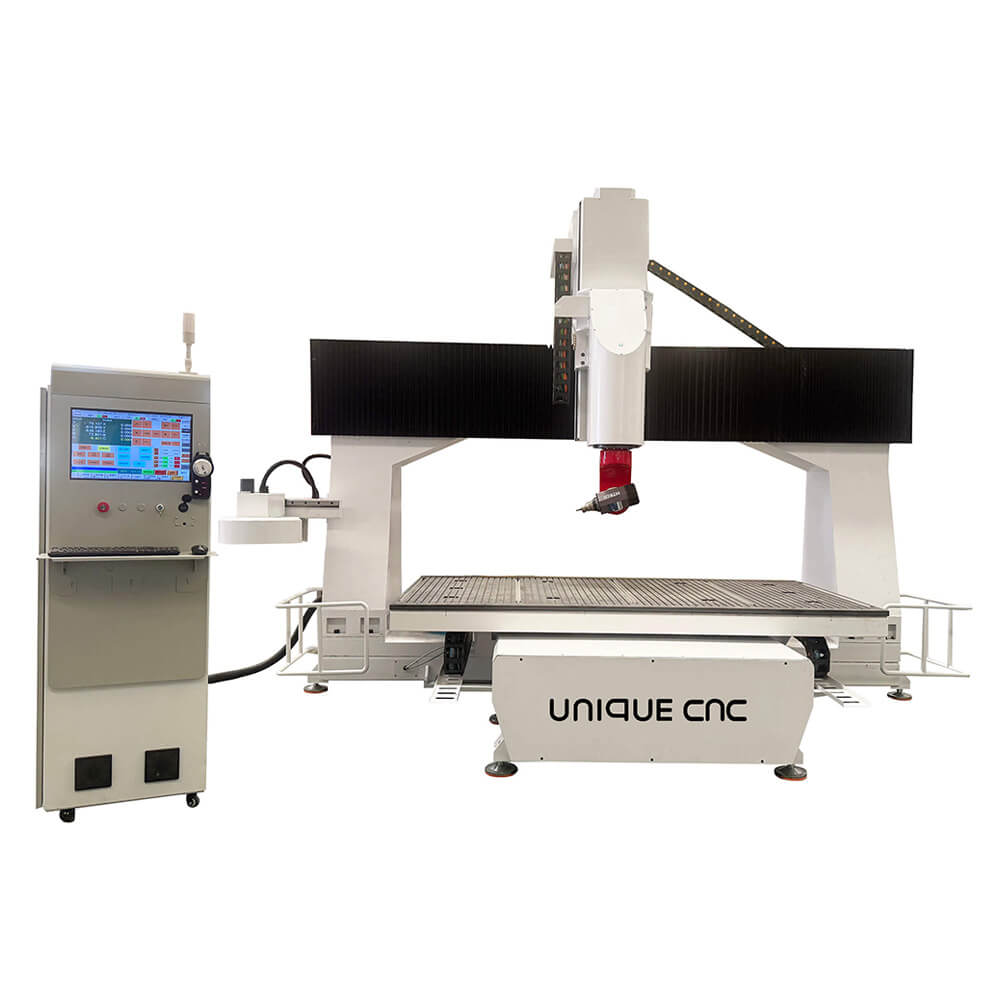

2025 Best Small 5 Axis CNC Router Machine

- Brand: UNIQUE CNC

- Model No.: U-R1325-5A

- Working Area: 1300*2500mm

- Price Range: $45,000-50,000 based on different configurations

- Standard: Meeting CE Standards in Terms of Quality & Safety

- Warranty: One-Year Limited Warranty for Entire Machine

- Shipping: Global Logistics and International Shipping for You

- Service: Lifetime Free Technical Support

- Support: Customized as per request

- Payment Term: TT, Credit Card,Paypal, Trade Assurance

Get A Quote

Table of Contents

What Is a Small 5 Axis CNC Router Machine?

A small 5 axis CNC router machine is a computer-numerical-controlled (CNC) machine that operates along five axes simultaneously: three linear axes (X, Y, Z) for horizontal, vertical, and depth movement, and two rotational axes (typically A and B or A and C) for tilting or rotating the workpiece or tool. Unlike larger industrial models, it has a compact design, making it suitable for small workshops, prototyping, or low-volume production.

Main Features of Unique CNC Small 5 Axis CNC Router

1. Compact Design.Floor space typically covers 1–3 square meters, fitting in small shops or factories.

2. High Precision.Processing accuracy can achieve 0.1mm,suitable for high-precision parts.

3. Advanced Syntec 5 Axis Control System with RTCP function.

The Syntec 5 axis CNC controller handles complex geometries in various industries and reduces setup time via single-setup multi-faced processing, optimizes tool angles for better finishes and longevity, features a friendly user interface for simplified programming, integrates with various CAD/CAM systems, and ensures reliable, durable performance.

4.Rigid Structure

The affordable 5 axis cnc router machine body is made from cast iron or welded steel structures. They are treat by sand casting and aging treatment to eliminate internal stresses, no deformation even after many years.The linear guides mounting surfaces, are hardened through quenching to enhance wear resistance. The bed surface is precision-machined by a German made milling center to achieve installation accuracy for high-precision linear guides with a flatness tolerance of <0.01mm/m. The rigid structures ensures optimal rigidity, vibration damping, and geometric precision for advanced 5-axis machining.

What Is the Advantage of the Vertical CNC Router?

When a horizontal spindle works with the rotary axis, it enables multi-angle rotational machining of workpieces, which is particularly suitable for carving cylindrical or curved workpieces.In contrast, a traditional vertically placed spindle faces spatial constraints during rotational machining. Besides, the rotary is mounted on the horizontal table, allowing it to hold various materials even without a tailstock.

Consideration for Use of The Vertical CNC Engraver

- Workpiece Limitations: The 4th axis is best for relatively small to -large sized parts,no matter the weight is light or heavy.

- Software Requirements: Requires 4-axis-compatible CAD/CAM software (e.g., Powermill,Mastercam,Fusion 360, VCarve Pro) to generate toolpaths.

- Calibration: The rotary axis must be precisely aligned with the machine’s coordinate system to avoid errors.

4 Axis Vertical CNC Engraving Machine Parameters

| Description | Parameters |

|---|---|

| Machine model | U-R680-4A |

| Working area | Diameter: 600mm, Height: 800mm |

| Machine structure | Steel |

| Driving system | Hybride Servo or Servo |

| Spindle | 1.5-3.0KW water cooling |

| Spindle speed | 0-24000rpm |

| Transmit way | High precision ballscrews |

| Guide rails | Linear square rails and bearings |

| Control system | CNC Control |

| Command | G code |

Mini Five Axis CNC Machine Applications

1. Precision Parts & Prototype Manufacturing

- Research & Product Development:Used in labs to quickly machine functional prototypes (e.g., robot joints, drone components) from aluminum, nylon, etc., enabling complex structures in one setup.

- Electronics & Communication Components:Creates complex 3D prototypes for consumer electronics (e.g., smartphone casings, wearable device components) with tight tolerances.

2. Woodworking & Musical Instrument Customization

- Small Musical Instrument Components: Machines ukulele bodies, violin headstock carvings, etc., using 5 axis machine for curved parts, reducing manual polishing.

- Wooden furniture:

- Dovetail Joints: Precision-cut interlocking joints for drawers or box corners.

- Mortise and Tenon: Strong, decorative joints for chair frames or table legs.

- Curved Components: Bentwood or sculpted legs, arms, or backs for chairs and sofas.

3. Cars Vehicle Automotive Decorative Components

The small size 5 aixs CNC machine can machining decorative trims and panels with 3D patterns, such as carbon fiber-like textures, geometric motifs, or brand logos, directly onto dashboard panels, door inserts, or center consoles.

4. Composite Materials & Lightweight Parts

- Drone & Model Aircraft Manufacturing: Cuts carbon fiber fuselage frames and fiberglass propellers, avoiding material delamination while achieving complex structures like weight-reducing grooves and irregular interfaces.

- Sports Equipment Accessories: Machines aluminum parts for ski bindings, golf club grip molds, etc., suitable for small-batch production of high-end products.

5. Artistic Creation & Personalized Customization

- 3D Sculptures and Organic Forms

- Art Prototyping and Editioning

- Dog,cats pet toys kennel and house

6. Small Mold & Tooling Production

- Small Mold Manufacturing:Produces injection mold cores (e.g., for toy parts) and stamping die inserts.

- Fixture & Jig Machining: Customizes small fixtures and gauges for CNC machines, using 5-axis machining to achieve multi-sided positioning structures and improve clamping efficiency.

Samples Made by the 4 Axis Vertical CNC Router

Frequently Asked Question

Here are the answers to the frequently asked questions from the experienced polyurethane mold CNC carving machine manufacturer.

CAM software like Mastercam,Powermill, Artcam, UG, Fusion360 are all good for this machine. These CAM software can convert 3D models into G – code, which is the command language understood by the CNC carving machine.

CAM software like Mastercam,Powermill, Artcam, UG, Fusion360 are all good for this machine. These CAM software can convert 3D models into G – code, which is the command language understood by the CNC carving machine.

This machine gives high – precision carving. The accuracy can reach up to 0.01 – 0.1 millimeters, depending on the model and its components. High – precision ball screws, linear guide rails, and advanced control systems contribute to this accuracy. This level of precision ensures that the orthotic molds fit the intended anatomical structure accurately, providing the necessary support and correction.

The carving time depends on several factors, including the complexity of the mold design, the size of the mold, and the cutting parameters set. For a relatively simple orthotic mold with a standard size, it may take around 30 minutes to 2 hours. More complex designs with intricate details or larger sizes can take 3 – 6 hours or even longer. Optimizing the cutting path in the CAM software can also help reduce the carving time.

Most manufacturers and suppliers of these vertical CNC carving machines offer training to help users get familiar with the machine’s operation, software usage, and basic maintenance. After – sales support is also typically provided, which may include technical assistance over the phone or online, software updates, and access to replacement parts. It is important to clarify the details of the training and after – sales support services before purchasing the machine to ensure a smooth experience during its use.

Regular maintenance is crucial to ensure the machine’s performance and longevity. This includes cleaning the machine after each use to remove foam debris, lubricating the linear guide rails and ball screws according to the manufacturer’s recommendations (usually every few months), checking and tightening any loose components, and periodically calibrating the machine to maintain accuracy. Additionally, it is important to keep the control system clean and free from dust and moisture.

Most Polyurethane PU Foam Orthotic Mold CNC Carving Machines can handle a range of foam densities. However, the cutting parameters such as spindle speed, feed rate, and cutting depth may need to be adjusted accordingly. Softer foams may require lower spindle speeds and slower feed rates to prevent excessive material removal or damage to the mold, while harder foams may need higher speeds and more aggressive cutting settings. It is advisable to test on sample materials first to determine the optimal parameters.

When operating the machine, always wear appropriate personal protective equipment, including safety glasses, earplugs (due to the noise generated during operation), and work gloves. Make sure the machine is properly grounded to avoid electrical hazards. Before starting a carving job, double – check that all safety guards are in place and functioning correctly. Do not reach into the working area while the machine is running, and follow the machine’s operating manual for proper startup, shutdown, and emergency stop procedures.

Yes, customized sizes are highly acceptable. The 4 Axis polyurethane CNC milling machine can be manufactured according to customer`s request.