How is an Orthopedic Mold CNC Router Revolutionizing Scoliosis Correction and Rosthetic Mold Fabrication?

Table of Contents

Introduction

Scoliosis, a spinal deformity affecting millions worldwide—particularly adolescents—often requires custom orthotic braces to manage curvature progression. Traditional brace manufacturing methods rely on manual molding, which can be time-consuming, inconsistent, and less precise. Today, polyurethane (PU) mold CNC technology is transforming scoliosis treatment by enabling faster, more accurate, and patient-specific orthotic solutions. In this blog, we explore how CNC machining of polyurethane molds is reshaping spinal care.

The Critical Role of Precision in Scoliosis Braces

Scoliosis braces, such as thoracolumbosacral orthoses (TLSO), work by applying targeted pressure to specific spinal regions to slow or halt curve progression. Success hinges on exact mold precision.

A misaligned brace can reduce effectiveness and increase discomfort.

Traditional plaster casting methods may introduce human error, leading to suboptimal fits.

Polyurethane molds carved by a orthopedic mold CNC Router can reduce the inconsistencies, ensuring braces mirror the patient’s unique spinal contours.

Why Polyurethane? Advantages for Orthotic Molds.

Polyurethane is the material of choice for scoliosis brace molds and prosthetic mold due to its wide advantages.

Durability: Withstands repeated use in high-pressure manufacturing environments.

Flexibility: Balances rigidity for structural support with enough give to accommodate patient movement.

Precision Replication: Captures anatomical details, crucial for accurate brace fitting.

Chemical Resistance: Resists degradation from cleaning agents, ensuring longevity in medical settings.

How CNC Technology Improves PU Mold Production?

3D Mold CNC (Computer Numerical Control) router machining uses automated, software-guided tools to carve molds from solid polyurethane blocks. Main benefits include:

Perfect Precision

Achieves best precision, translating 3D scans of the patient’s spine into physical molds with minimal deviation.

Reduces the need for post-production adjustments, streamlining the brace-fitting process.

Speed & Efficiency

Cuts production time from days (traditional methods) to hours, critical for patients needing urgent treatment.

Enables rapid prototyping, allowing clinicians to test multiple brace designs before finalizing.

Customization at Scale

Easily adapts to patient-specific geometries, whether for pediatric, adolescent, or adult scoliosis cases.Ideal for complex spinal curvatures.

Integration with 3D Scanning

Seamlessly pairs with 3D body scanners to create digital models that are directly translated into CNC programs.

Reduces manual measurements, minimizing human error and improving patient comfort during the scanning process.

Real-World Impact: Case Studies

Pediatric Scoliosis Treatment: A children’s hospital reported a 40% reduction in brace adjustment visits after switching to CNC-machined PU molds. Patients also reported 30% higher comfort levels due to better fit.

Adolescent Idiopathic Scoliosis (AIS): A clinical trial comparing CNC-produced braces to traditional models showed a 22% greater improvement in spinal alignment over six months.

Addressing Common Concerns

Cost: While initial orthopedic mold CNC carving milling machine investment is higher, long-term savings accrue from reduced labor, fewer revisions, and faster production cycles.

Material Safety: Medical-grade polyurethane is biocompatible and approved for contact with skin, ensuring patient safety.

Training Requirements: Modern CNC systems feature user-friendly interfaces, minimizing the learning curve for orthotists.

The Future of Scoliosis Care and Prosthetic Mold Fabrication

AI Integration: Machine learning algorithms may soon predict optimal brace designs based on spinal curvature data.

On-Demand Manufacturing: Point-of-care CNC units could enable same-day brace production in clinics.

Sustainability: Eco-friendly polyurethane formulations are emerging, aligning with healthcare’s growing focus on green practices.

Conclusion

Polyurethane mold CNC carving technology is revolutionizing scoliosis correction by merging precision engineering with patient-centric care and prosthetic mold production. By delivering custom orthotics faster, more accurately, and with greater comfort, CNC-machined PU molds are not just a technological upgrade—they’re a game-changer for patients and clinicians alike.

Comments

Related Products

How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

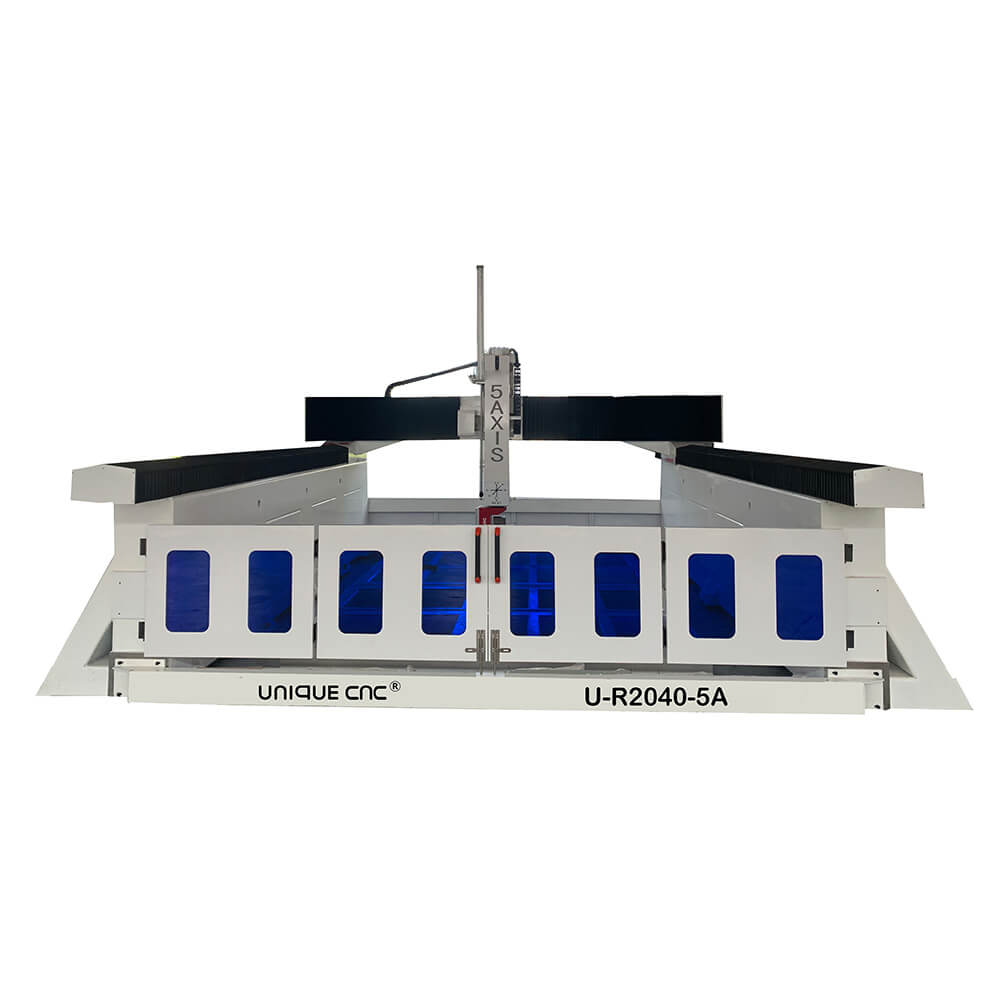

How 5 Axis CNC Routers Revolutionize Automotive Interior Manufacturing?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

Tags

The Application of 5-axis CNC Engraving Machines in Epoxy Resin Molds

Epoxy resin molds are made with epoxy resin as the main material, combined with curing agents and various reinforcing materials.

How to make Polyurethane Molds by a 4 Axis Polyurethane Carving CNC?

CNC carving is revolutionizing the production of polyurethane molds, offering unmatched precision, consistency, and speed.

How is an Orthopedic Mold CNC Router Revolutionizing Scoliosis Correction and Rosthetic Mold Fabrication?

Orthopedic molds carved by a CNC carving machine can reduce the inconsistencies, ensuring braces mirror the patient’s unique spinal contours.