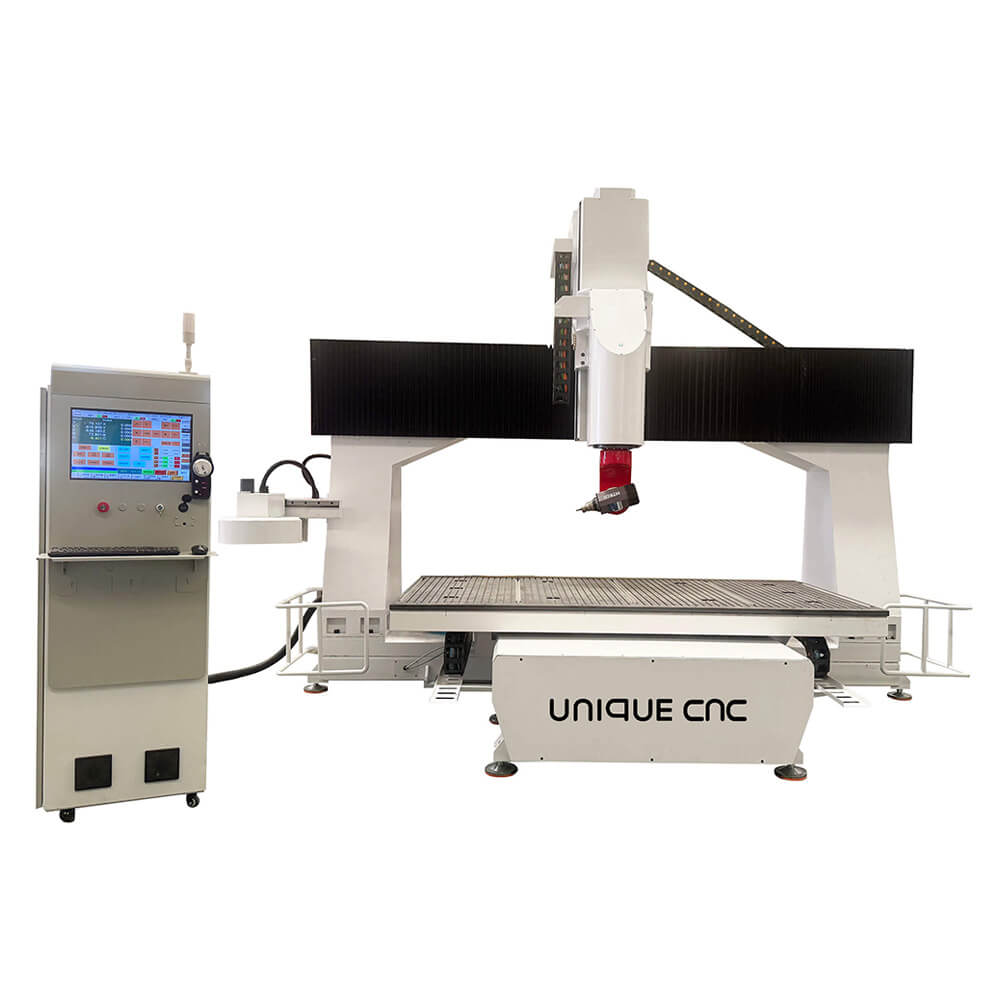

Polyurethane PU Foam Orthotic Mold CNC Carving Machine

This polyurethane mold CNC carving machine is designed for working with polyurethane foam molds. This CNC carving machine is built to provide high accuracy, which is crucial for making medical devices that fit patients perfectly and work well. Whether it’s creating spinal braces or custom-made orthotic insoles, this foam mold CNC machine combines the latest technology with a focus on patient needs.

- Brand: UNIQUE CNC

- Model No.: U-R680-4A

- Working Diameter: 680mm (27")

- Standard: Meeting CE Standards in Terms of Quality & Safety

- Warranty: One-Year Limited Warranty for Entire Machine

- Shipping: Global Logistics and International Shipping for You

- Service: Lifetime Free Technical Support

- Support: Customized as per request

- Payment Term: TT, Credit Card,Paypal, Trade Assurance

Get A Quote

Table of Contents

Polyurethane PU Foam Orthotic Mold CNC Engraving Machine:Revolutionizing Orthopedic Solutions

Specifically designed for orthopedic applications, our 4-axis CNC milling carving machines use polyurethane (PU) foam to create customized braces, spinal orthoses, and scoliosis correction devices with unparalleled accuracy. Revolutionize patient outcomes and treatment efficiency with our advanced foam machining technology.

What Is a Polyurethane Orthotic Mold CNC Carving Machine?

- It crafts personalized orthopedic devices that conform precisely to a patient’s unique body shape, especially crucial for scoliosis correction where a perfect fit can significantly enhance treatment effectiveness.

- By working with PU foam, a lightweight yet durable material, it produces devices that offer comfort and support during extended use.

- Ensures high precision in creating intricate shapes required for spinal orthoses and braces, minimizing the margin of error in patient care.

Advantages of the PU foam CNC Milling Machine?

- 4-Axis Configuration: The combination of X, Y, Z linear axes and the A-axis rotation allows for the production of highly complex and customized orthopedic molds, ensuring that each device fits the patient’s anatomy perfectly.

- Durable Spindle: With a 3KW water cooling spindle speed reaching up to 24,000 RPM, it efficiently cuts through PU foam, reducing production time for urgent orthopedic cases.

- Varioius Working Area: Customizable from 300mm to 800mm, it can accommodate foam blocks of various sizes, suitable for different orthopedic device requirements, from small joint braces to full – body spinal orthoses.

- Control System: an easy operation control system with programming interface makes it easy to input patient – specific measurements and design requirements, streamlining the production process.

- Dust Collection System: An integrated vacuum system maintains a clean working environment, which is essential in medical device production to ensure hygiene and quality.

Technical Parameters of the Polyurethane CNC Router Carving Machine

| Description | Parameters |

|---|---|

| Machine model | U-R680-4A |

| Working area | Diameter: 680mm, Height: 800mm |

| Machine structure | Steel |

| Driving system | Servo driving |

| Spindle | 3KW water cooling |

| Spindle speed | 0-24000rpm |

| Transmit way | High precision ballscrews |

| Guide rails | Linear square rails and bearings |

| Control system | CNC Control |

| Command | G code |

4 Axis Mold CNC Engraving Machine Applications in Orthopedics

- Custom Braces: Our 4-axis CNC engraving machines create custom scoliosis braces that adapt precisely to the curvature of the patient’s spine. By using PU foam, the braces are lightweight, reducing patient discomfort while providing the necessary support to correct spinal deformities.

- Treatment Efficiency: The high precision of the machine ensures that each brace fits snugly, maximizing the effectiveness of the treatment. This can lead to faster correction and better long – term outcomes for patients with scoliosis.

- Spinal Orthoses: For patients recovering from spinal injuries or surgeries, our machines produce spinal orthoses that offer targeted support to the affected area. The customized fit helps in proper alignment and faster healing.

- Joint Braces: Whether for knee, ankle, or wrist injuries, the four axis polyurethane CNC milling technology enables the creation of braces that provide optimal compression and stability, promoting recovery and reducing pain.

Advantages of 4-Axis CNC Milling in Orthopedic Device Production

- Personalized Treatment: The 4th axis allows for the creation of highly customized devices based on individual patient scans. This personalized approach in scoliosis correction and other orthopedic treatments improves patient compliance and treatment success rates.

- Time and Cost Efficiency: By automating the foam machining process, our 4-axis machines reduce production time compared to traditional methods. This not only speeds up patient access to treatment but also lowers overall production costs.

- Material Optimization: The precise toolpaths of the 4-axis machine minimize PU foam waste, making the production of orthopedic devices more sustainable and cost – effective.

Why Choose Our CNC Milling Machines for Orthopedics?

- Medical – Grade Precision: Our machines meet strict medical standards, ensuring that every orthopedic device produced is of the highest quality and safety.

- Expert Support: Our team of engineers and technicians has extensive experience in orthopedic applications. We offer comprehensive support, from initial design to final production, to help you create the best – in – class orthopedic devices.

- Integration with Medical Data: Our CNC systems can easily integrate with 3D patient scans and medical imaging data, allowing for seamless translation of anatomical information into customized orthopedic molds.

Frequently Asked Question

Here are the answers to the frequently asked questions from the experienced polyurethane mold CNC carving machine manufacturer.

CAM software like Mastercam,Powermill, Artcam, UG, Fusion360 are all good for this machine. These CAM software can convert 3D models into G – code, which is the command language understood by the CNC carving machine.

This machine gives high – precision carving. The accuracy can reach up to 0.01 – 0.1 millimeters, depending on the model and its components. High – precision ball screws, linear guide rails, and advanced control systems contribute to this accuracy. This level of precision ensures that the orthotic molds fit the intended anatomical structure accurately, providing the necessary support and correction.

The carving time depends on several factors, including the complexity of the mold design, the size of the mold, and the cutting parameters set. For a relatively simple orthotic mold with a standard size, it may take around 30 minutes to 2 hours. More complex designs with intricate details or larger sizes can take 3 – 6 hours or even longer. Optimizing the cutting path in the CAM software can also help reduce the carving time.

Most manufacturers and suppliers of these CNC carving machines offer training to help users get familiar with the machine’s operation, software usage, and basic maintenance. After – sales support is also typically provided, which may include technical assistance over the phone or online, software updates, and access to replacement parts. It is important to clarify the details of the training and after – sales support services before purchasing the machine to ensure a smooth experience during its use.

Regular maintenance is crucial to ensure the machine’s performance and longevity. This includes cleaning the machine after each use to remove foam debris, lubricating the linear guide rails and ball screws according to the manufacturer’s recommendations (usually every few months), checking and tightening any loose components, and periodically calibrating the machine to maintain accuracy. Additionally, it is important to keep the control system clean and free from dust and moisture.

Most Polyurethane PU Foam Orthotic Mold CNC Carving Machines can handle a range of foam densities. However, the cutting parameters such as spindle speed, feed rate, and cutting depth may need to be adjusted accordingly. Softer foams may require lower spindle speeds and slower feed rates to prevent excessive material removal or damage to the mold, while harder foams may need higher speeds and more aggressive cutting settings. It is advisable to test on sample materials first to determine the optimal parameters.

When operating the machine, always wear appropriate personal protective equipment, including safety glasses, earplugs (due to the noise generated during operation), and work gloves. Make sure the machine is properly grounded to avoid electrical hazards. Before starting a carving job, double – check that all safety guards are in place and functioning correctly. Do not reach into the working area while the machine is running, and follow the machine’s operating manual for proper startup, shutdown, and emergency stop procedures.

Yes, customized sizes are highly acceptable. The 4 Axis polyurethane CNC milling machine can be manufactured according to customer`s request.